Definition of light commercial refrigeration and compressor segmentation applications

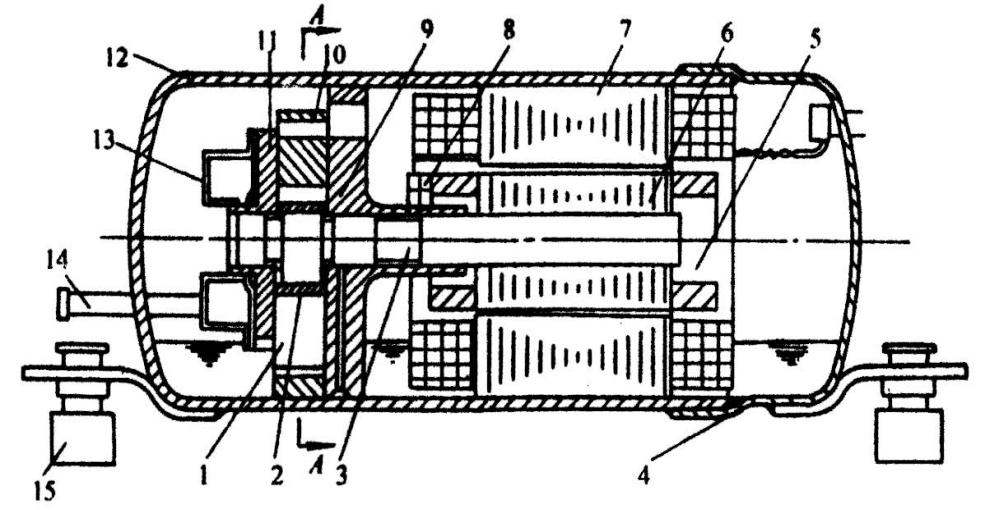

Refrigeration equipment can be divided into household and commercial according to its purpose, and commercial refrigeration can be divided into light commercial and heavy-duty commercial. At present, most mainstream household refrigeration and refrigeration scenarios represented by household refrigerators and freezers use reciprocating piston compressors. In light commercial refrigeration and refrigeration scenarios (mainly including refrigeration display cabinets, commercial ice machines, cold storage, kitchen refrigerators, and medical freezers, automatic sales Cargo aircraft, vehicle refrigerators) reciprocating piston, rotary and scroll compressors are all used. Among them, reciprocating piston compressors are mainly used in household refrigerators and freezers ≤1.5HP. Rotary compressors mainly occupy the mainstream in the light commercial refrigeration field in the 1-3HP power range. The 3-5HP power range is gradually replacing scroll compressor. machine, and scroll compressors account for a large proportion of applications in the ≥5HP market.

Comparison of structure, performance and economic characteristics of piston, rotaryand scroll compressor

The three types of compressors are usually called first-generation, second-generation, and third-generation compressors according to their birth time. The characteristics of the three types of compressors are compared as follows:

| project | piston | rotary | scroll |

| Principles of mechanical motion | linear reciprocating motion | circular rotational motion | rotational translation |

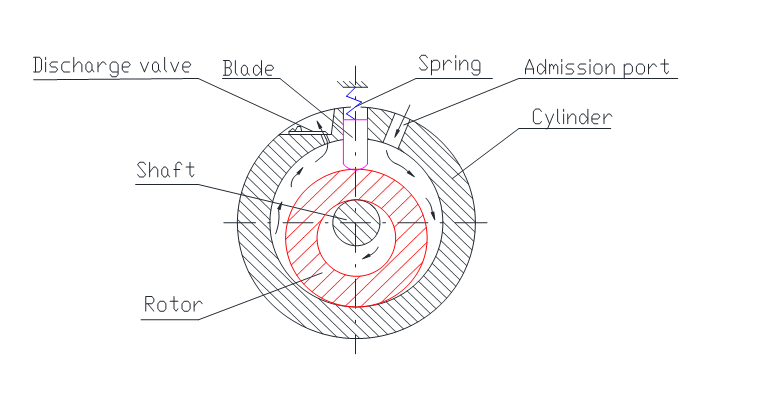

| Structural features | Crank connecting rod structure, the motor stator and the pump body are fastened together with bolts, the entire movement is internally supported by suspension springs or compression springs , and the structure is compact . | The eccentric pin drives the circular rolling rotor to rotate in the cylinder. The pump body and motor are directly fixed on the shell. It has no suction valve, small size and light weight. | The meshing of the scroll rotor and the scroll stator is used to form multiple compression chambers. With the translational rotation of the scroll rotor, the volume of each compression chamber continuously changes to realize the compression of the medium. It has a simple structure, small volume, light weight, and no Valves and other wearing parts. |

| Performance characteristics | Due to the internal spring structure and muffler cavity, vibration caused by changes in crankshaft torque can be avoided from being transmitted to the housing, so the vibration is small and the noise is low. | It has high efficiency (small clearance volume, no overheating of the suction air, and 20%-30% higher indicating efficiency than the reciprocating type). The average performance coefficient is 20% higher than that of the piston engine. It has good performance under variable working conditions and high reliability. | The clearance-free volume and volume coefficient are 10% higher than that of the rotor machine. It has good speed changeability, multiple cavities work simultaneously, uniform torque, and good machine balance. Therefore, it has small vibration, low noise, stable operation, high reliability, and is suitable for fixed small pressures. Refrigerant with relatively low operating pressure. |

| Manufacturing features | The number of parts is ≥80, the processing structure of the cylinder, piston, and connecting rod is relatively complex, the pump body has many casting surfaces, and consumes a lot of raw materials . | The number of parts is 1/3 less than that of the piston machine . The parts have simple shapes, mostly cylindrical, arc or flat surfaces. The processing technology is simple and the cost is low. | The main components are only 1/10 of the piston machine , and the volume is reduced by about 30%. The high-precision scroll profile is relatively complex, mostly in a curved shape , making processing and inspection difficult and costly. |

| Application status | Mainly used in the field of refrigeration, it has an absolute advantage in the household refrigeration market below 1HP. | Relying on cost advantages and continuously improving technical levels, application scenarios are becoming more and more diversified. The field of household air conditioning has an absolute advantage. The applications in emerging markets such as heat pumps and refrigeration and refrigeration are gradually expanding, showing a trend of gradually replacing some piston machines and scroll machines. | It has some applications in the fields of air conditioning, heat pumps and refrigeration. The power range is mainly concentrated in 3-15HP. The 3-5HP power range is gradually being replaced by rotor machines. It is ushering in new fields such as refrigeration, low-temperature heat pumps and new energy vehicles. Development Opportunities. |

Analysis of light commercial refrigeration application working conditions and comparative analysis of measured data of piston machines and rotarymachines

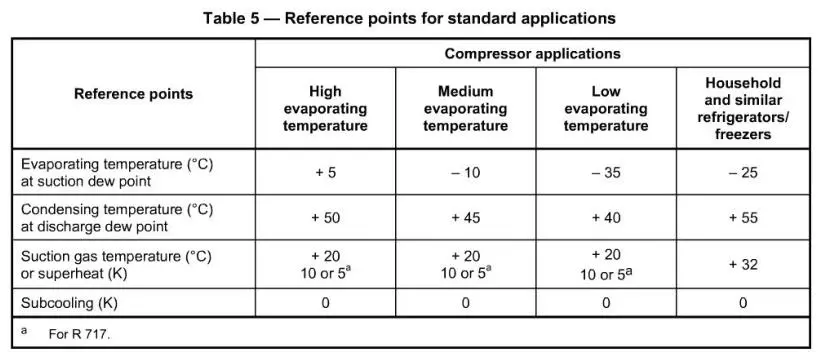

According to the evaporating temperature of light commercial refrigeration equipment, EN12900 divides the compressor application conditions into: high temperature, medium and low temperature.

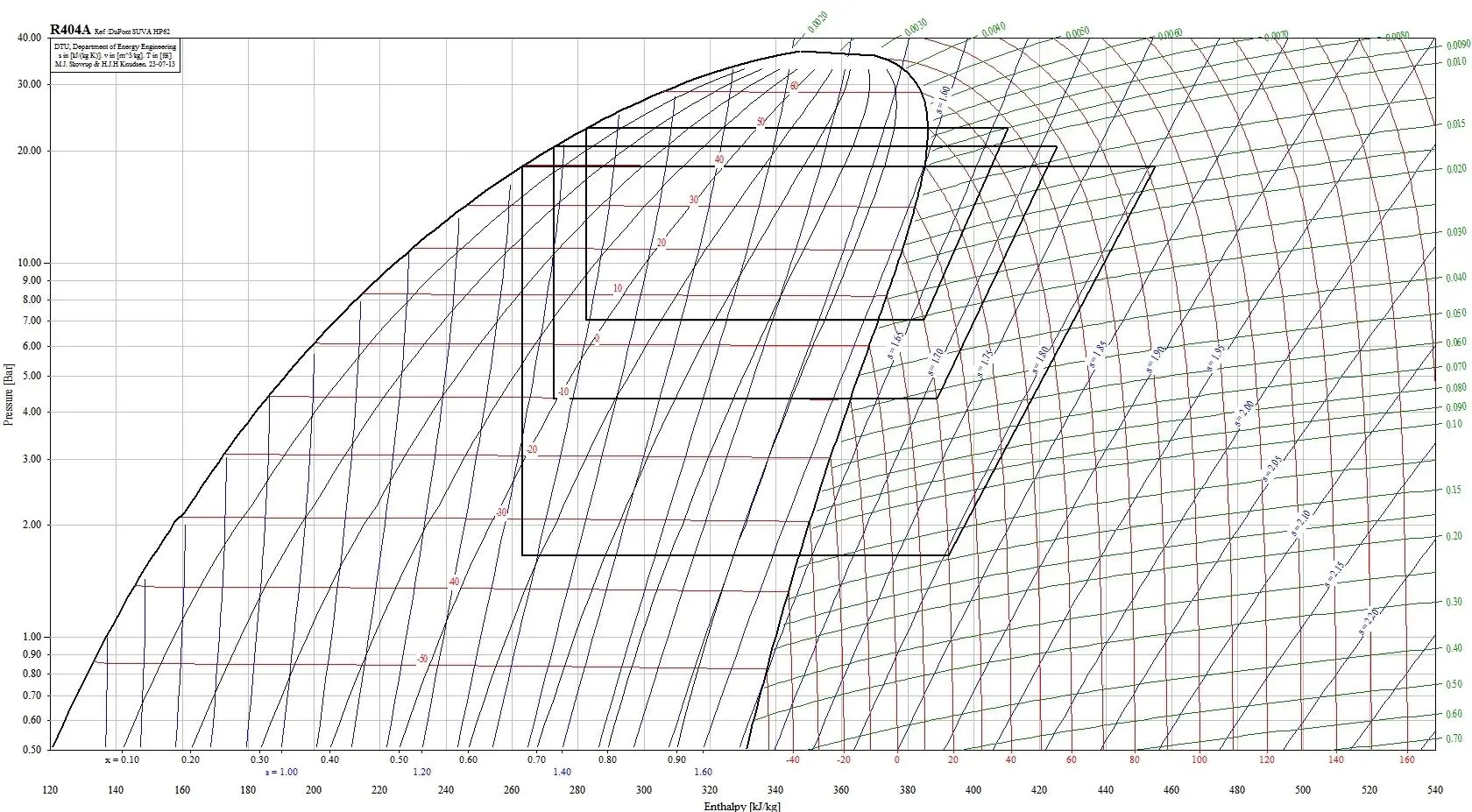

Comparison of theoretical pressure-enthalpy diagrams under EN12900 high temperature, medium temperature and low temperature conditions

By comparing the theoretical refrigeration cycle characteristics of the three working conditions, it can be seen that:

| EN12900 working conditions | Theoretical exhaust temperature (℃) | Compression ratio (condensing pressure/evaporating pressure) | Theoretical circulation mass flow (based on high temperature working conditions) |

| high temperature | 69 | 3.26 | 1 |

| medium temperature | 78 | 4.72 | 58% |

| low temperature | 103 | 11 | twenty one% |

From high-temperature working conditions to low-temperature working conditions, as the system evaporation temperature decreases, the theoretical discharge temperature of the compressor gradually increases, the pressure ratio becomes larger and larger, and the compressor circulation flow decreases sharply. Under low-temperature conditions with low evaporation temperature, the compressor will operate under a large pressure ratio, small flow rate, and high discharge temperature for a long time. Under these working conditions, no matter what kind of compressor it is, it will cause damage to the compressor motor and pump body mechanical structure. Reliability brings huge challenges. In order to cope with the above unfavorable conditions under low-temperature conditions, we adopt a new type of rotary compressor with an injection structure. By injecting cooling liquid into the compression chamber, we effectively reduce the compressor discharge temperature and increase the compression cycle flow. The refrigeration capacity of the compressor has been improved; in addition, we have carried out new surface treatments and optimized the oiling channel structure of the rotor compressor crankshaft, sliding vanes and other parts that are prone to wear and tear, thereby improving the wear resistance of the parts and the compressor lubrication effect, which can Ensure that the compressor works reliably under low temperature conditions and high compression ratio conditions.

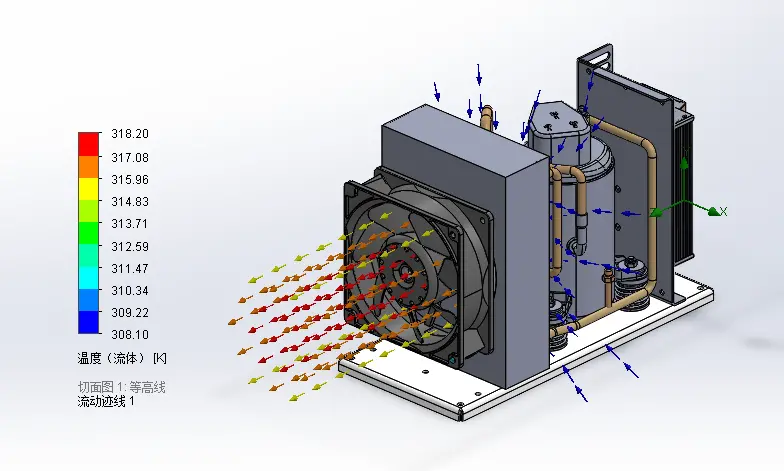

The following is a comparison of the test data between a certain model of our company's horizontal double-rotor refrigeration compressor and a foreign brand piston machine under the evaporation temperature conditions of -23.3°C and -6.7°C:

| Product number | Power supply/refrigerant | weight/displacement | Refrigeration capacity (W) | Power (W) | Energy efficiency (w/w) | Exhaust temperature (℃) | Noise (dB(A)) |

| A foreign brand

NJ2212GK |

AC230~50HZ | 21.45Kg | (refrigerated) 2875W | 1913W | 1.5 | 116.6 | 51.6 |

| R404A | 34.38cc/rev | (frozen) 1377W | 1239W | 1. 0 1 | 132.4 | 46.4 | |

| Boyang THSD329KS | AC230~50HZ | 19.8Kg | (refrigerated) 3621W | 2124 | 1.7 | 69.3 | 55.4 (52.6) |

| R404A | 32.9cc/rev | (frozen) 1854W | 1530 | 1.21 _ | 74.5 | 55 (50) |

Remarks: The noise test data of our company’s compressors in brackets are the data of the compressor covered with sound insulation cotton.

From the above measured data, we can see:

- Our THSD329KS horizontal double-rotor refrigeration and refrigeration compressor has a refrigeration capacity that is 30%-40% higher than that of a foreign brand piston machine of the same displacement, both in refrigeration and freezing conditions, and the refrigeration energy efficiency is more than 13% higher;

- Under refrigeration conditions (-23.3°C), the piston engine is basically in the extreme boundary state of operation (the exhaust temperature has exceeded 130°C). However, because our compressor adopts a quasi-two-stage compression structure with an injection injection circuit, the compressor exhaust The temperature can be controlled within 80°C, effectively ensuring the reliability of the compressor;

- The piston machine has low noise due to its good internal damping spring and muffler settings. After our rotor machine is covered with sound insulation cotton, the compressor noise value is basically close to that of the piston machine, and the performance in the refrigeration system is equivalent.

in conclusion

Through the theoretical analysis and comparison of the piston, rotor and scroll of the three-generation compressors with the largest volume in the industry today, this article selects similar arrangements for the two structural types of compressors - piston and rotary - commonly used in the light commercial refrigeration and refrigeration field, 1-3HP. Through comparative testing and analysis of mass products, combined with the characteristics of the theoretical refrigeration cycle under refrigeration and refrigeration conditions, the following conclusions are drawn:

- The rotary compressor has a simple structure and a mature manufacturing and processing system. It has high refrigeration performance, reliability and technical maturity. It has good variable working conditions and variable speed performance. It can be designed as a single-machine quasi-two-stage or two-cylinder two-stage design, which can meet the needs in the field of light commercial refrigeration applications, it has high application requirements such as large pressure ratio, small flow rate, and high discharge temperature. It has the natural application advantages of high reliability, high performance, and low cost, and is very suitable for 1-3HP light commercial refrigeration applications;

- The new liquid-injection rotary compressor has better performance and higher reliability than the piston compressor when used in light commercial fields, and is more in line with the environmental policy requirements of energy conservation and carbon reduction.