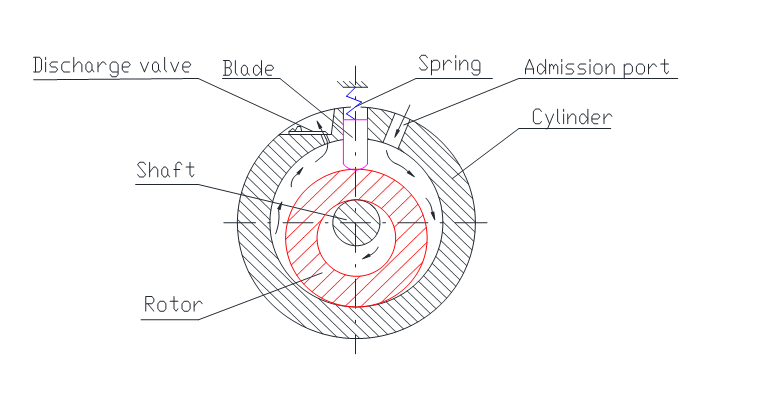

Rotor compressor is a kind of rotating mechanism compressor. According to the classification of working principle, it belongs to a positive displacement rotary compressor. Its working principle is shown below:

Working principle diagram of rotor compressor

Rotor compression has a long history and is one of the most mature and reliable compression technologies. As early as 1857, a rotary mechanism was considered to make a liquid pump as a compressor for refrigerators.

- In 1919, the first rolling rotor compressor prototype was producedin France.

- In 1931, Vilter in the United States first applied the rolling rotor compressor to GM refrigerators, and realized the industrialization.

- In 1950, GE installed the rolling rotor compressor in the air conditioner (window unit), replacing the piston compressor in the air conditioner.

- In 1970, some Japanese companies introduced or referred to GE technology for secondary development to greatly improve the machining accuracy, adopt new motor materials, and upgrade the rotor compressor technology.

- After 70 s, rolling rotor compressors are taking an increasing proportion in small fully-enclosed refrigeration compressors, and is widely used in room air conditioners, refrigerators, and small commercial refrigeration equipment.

- In the early 90 s,rolling rotor compressors are rapidly popularized in China and widely used in the field of household air conditioning.

- Since 2000, rolling rotor compressor has developed rapidly in many fields, such as household, automobile, commercial and industrial.

From the perspective of rotor compressor technology and industrial development history, rotor compressor was born in France, grew up in the United States, further developed in Japan, and finally successfully rose in the Chinese market. China is currently the largest producer and consumer market for rotor compressors.

At present, the rotor compressor market and technology development presents the following characteristics:

- Diversified application scenarios

Rotor compressors are mainly used in household and light commercial fields. In recent years, as rotor compressor technology continues to mature and product stability is increasingly improved, rotor compressor application scenarios are more and more diversified. From the beginning, the rotor compressor mainly used in air conditioning, gradually expanded to heat pumps and refrigeration and refrigeration, and launched a strong challenge in different applications. For example, in the field of air conditioning and heat pumps, the development of rotor compressor to high power segment is eroding the scroll compressor market. In the field of refrigeration, the rotor compressor has successfully replaced part of the fully sealed piston market in addition to the continuous extrusion scroll compressor market. It can be said that with cost advantages and constantly improving technical level, rotor compressor has shown a good momentum of development in various fields. In terms of sales volume, air conditioning has always been the largest market for rotor compressors, but in recent years, affected by the stagnancy of the real estate market, the market for rotor compressors for air conditioning is close to saturation, and the development has been relatively gentle. However, heat pump and refrigeration and other emerging areas belong to the relatively segmented market, so the development of rotor compressors is faster and there is more room for its growth.

- Refrigerants more low-carbon and environmental

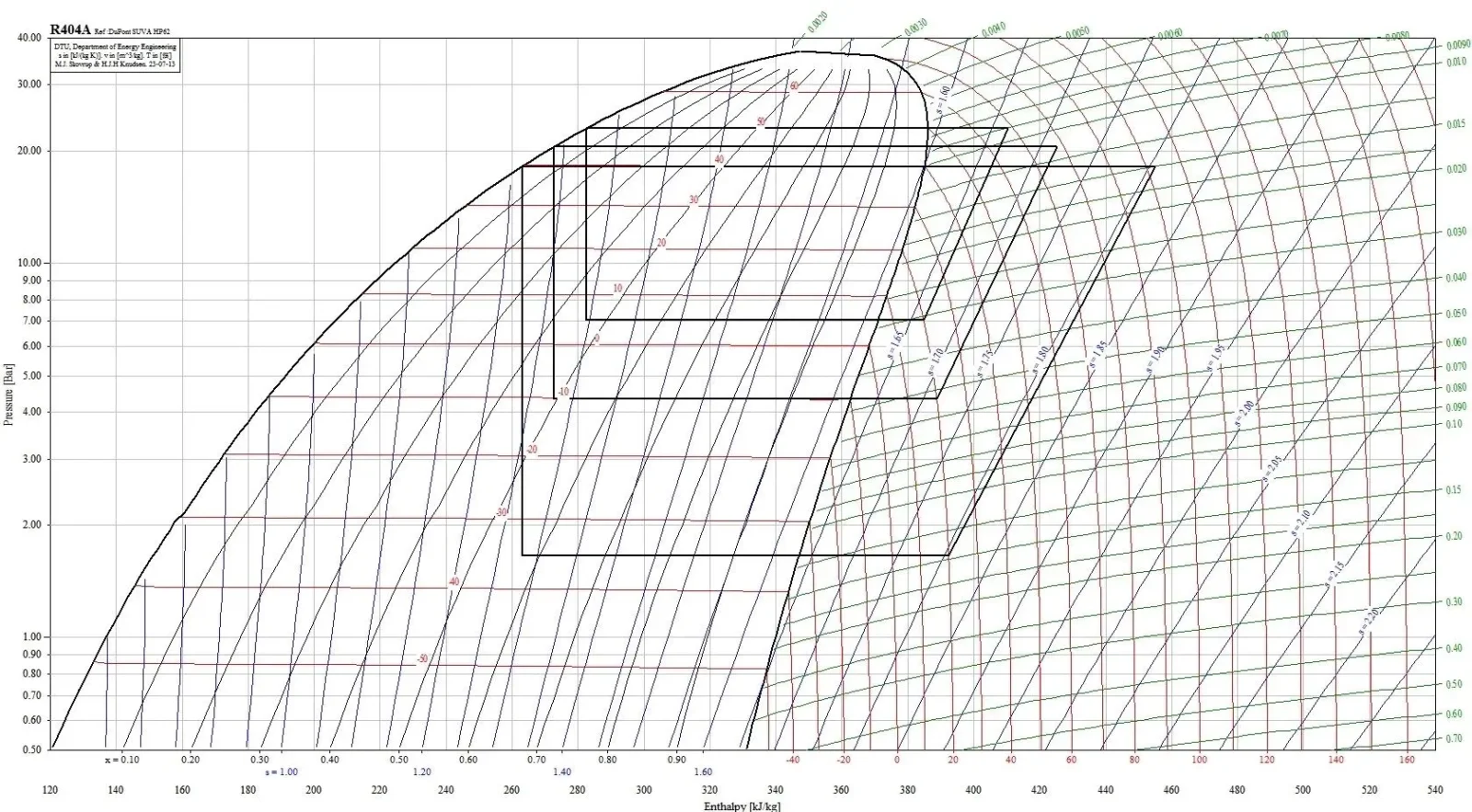

The main refrigerant for the rotor compressor is R410A, R32, R22 and R404A. As the social demand for environmental protection and energy efficiency improvement has been paid more attention, the application of environmentally friendly refrigerants has become an inevitable trend. At present, the whole rotor compressor industry is rapidly switching to HFCs and HCs, steadily replacing R22 and R410A market. In some enterprises, R32 compressors account for more than or nearly half of the total. In terms of natural working medium, R290 has been identified by the European Union as an alternative refrigerant development direction.

The following policies related to refrigerant replacement are noteworthy:

- From 1st January 2020, the export of products containing fluorine gas with GWP≥150, including commercial refrigerators and freezers, has been banned to the EU market .

- From January 2025, the use of fluorinated greenhouse gases with GWP of more than 150 will be prohibited for integrated machines (including plug and play rooms and self-contained air-conditioning and heat pump equipment).

- From 1st January 2028, the use of HFCs in split air conditioners and heat pumps below 12KW will be prohibited.

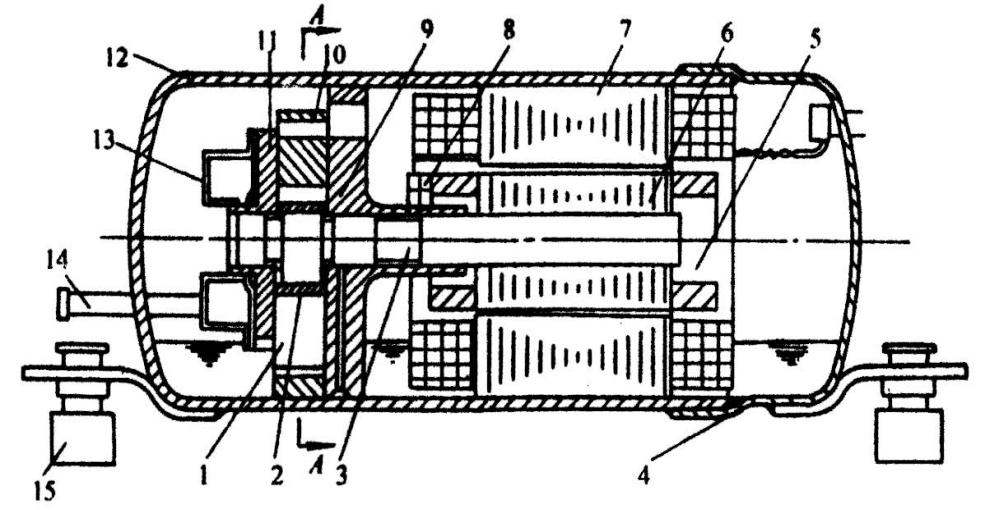

For example, Horizontal rotor compressors possess natural advantages and are widely used in scenarios where the installation space of compressors is limited, such as small refrigeration equipment and vehicle air conditioners. In the field of vehicle refrigerator and heat pump dryer, miniaturized internal two-cylinder compressor is more suitable. Compressor frequency conversion will be more in line with the development trend of energy saving, environmental protection, low carbon and high efficiency. In the application scenarios of high temperature heat pump and low temperature refrigeration, enhanced vapor injection and two-stage compression technology will make the realization of the target easier and more reliable.